Today’s chemistry labs are about working smarter, not harder. Higher reproducibility and speed are increasing throughput and research quality. No longer saddled with tedious, repetitive tasks, scientists are finally being freed to focus on more creative aspects of their work.

This article features Dr. Daniel Chartrand, Ph.D., and the automation platform he built at the University of Montreal (U of M). The platform is intended to accelerate the University’s research on solar cells, for greener, cleaner energy.

Dr. Chartrand needed to automate the fabrication and characterization of small test solar cells in inert atmosphere enclosures.

Solar cells

Solar cells generate energy when light, or photons, are absorbed by semiconducting materials and converted into electricity. Solar cell devices are the electrical building blocks of solar panels. Commonly used to produce clean energy, they can also detect light and measure its intensity.

Solar cell production isn’t always environmentally friendly due to the materials and energy it consumes. That’s why researchers worldwide are seeking better ways to produce them.

Dr. Chartrand’s system provides researchers at the U of M chemistry lab with a fast automation platform to explore new solar cell materials and production methods.

Automation challenges

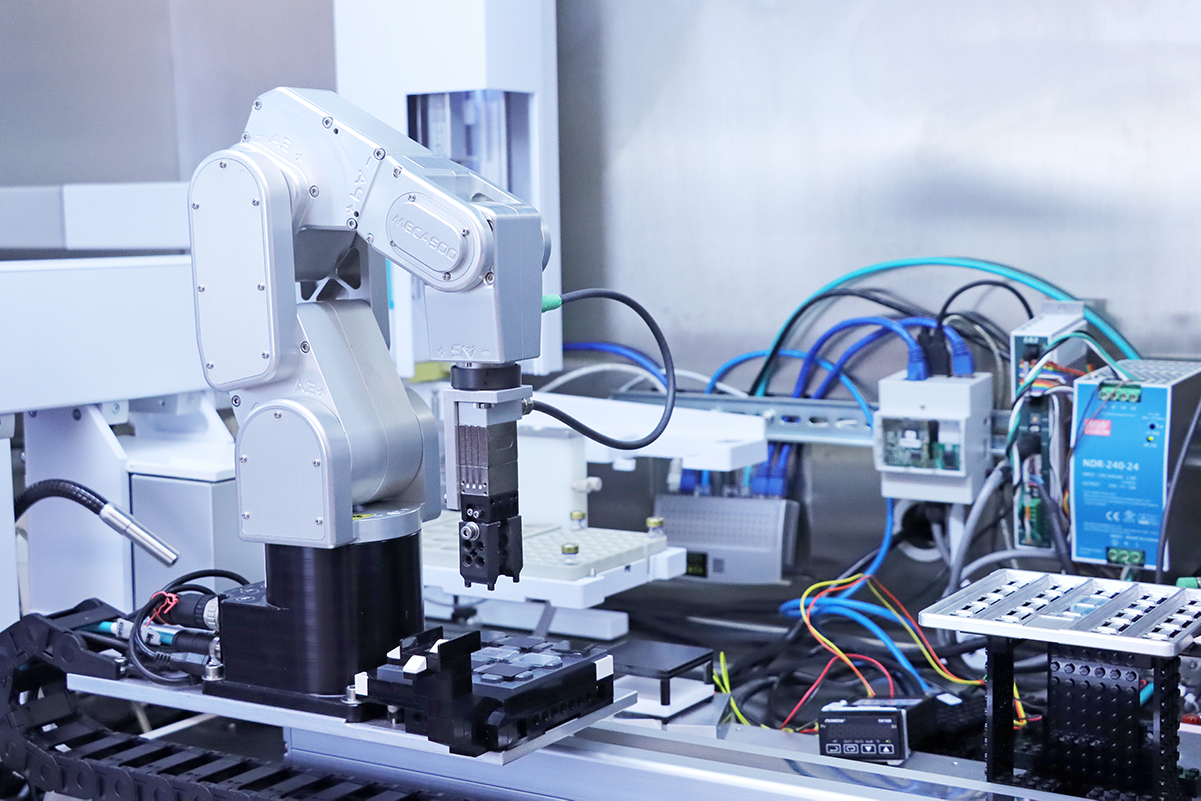

The glass substrates needed for this research are delicate. Each must be carefully handled inside an inert atmosphere chamber under exactly the same conditions. This challenge called for a small, compact, but highly precise robot able to maneuver in a cramped space. In addition, the platform’s components needed to be affordable, but highly reliable, and easy to use.

Solutions

For the robot component, Dr. Chartrand selected the world’s smallest six-axis robotic arm, the Meca500. Mounting the robot on a linear axis greatly enhanced its reach, beyond what would have been possibly gained from using a bigger robot. The robot’s minute and reproducible positioning removed the need for an alignment system using vision or other means.

From manual to robotized movements

Benefits

.jpg)

About Dr. Chartrand

Dr. Daniel Chartrand holds a Ph.D. in Coordination Chemistry from the University of Montreal, where he has been working for the past fourteen years. He’s currently a Research Advisor at the Department of Chemistry’s Laboratory of Analysis of Materials’ and Molecules’ Photoactivity (LAMP). Dr. Chartrand has developed a passion for designing and implementing automations to enhance throughput of analytical techniques, such as this robotized characterization of solar devices.

The University of Montreal

The University de Montreal is one of the world’s leading research universities. Established in 1878, in Montreal, Quebec, the university aims to contribute to societal wellness by placing itself at the forefront of knowledge. With this goal, the university inaugurated a new state-of-the-art science complex known as the MIL Campus in 2019, for cutting-edge research. Learn more >

Learn more about Mecademic’s products and solutions

Ready to find out how our products and solutions can increase your production throughput within the smallest possible footprint, without sacrificing precision, or reach?